Augmented Reality for Industry 4.0

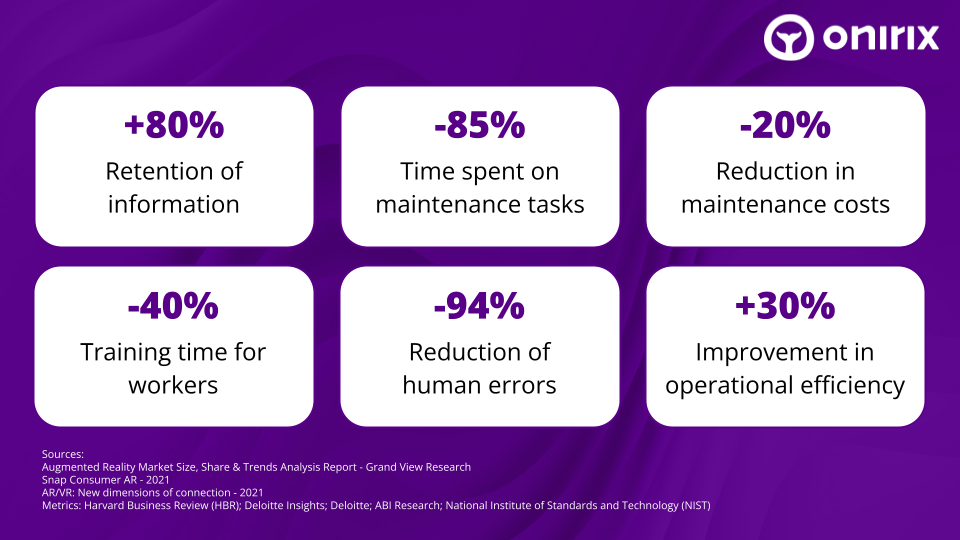

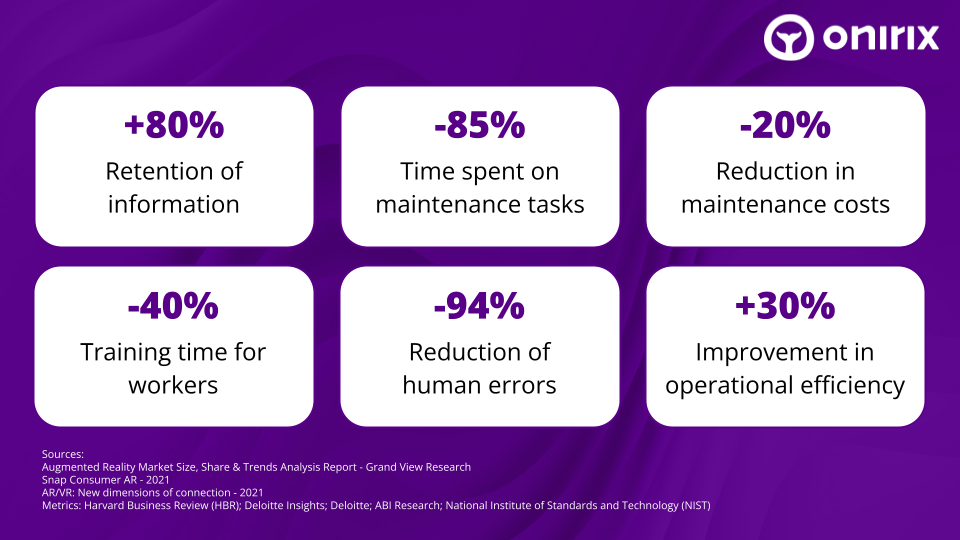

Why is Augmented Reality so useful in Industry 4.0? The key lies in its significant business impact, as illustrated by the following figures:

Augmented Reality (AR) is a technology that adds an extra digital dimension to the real world by superimposing information such as text, images and sound on our surroundings.

This creates an interactive experience of an existing real environment enhanced by computer-generated images. For example, smart glasses (headsets) or a smartphone can provide real-time information to an operator monitoring a production plant.

Industry 4.0, also known as Smart Industry or the Fourth Industrial Revolution, represents a paradigm shift in manufacturing. It involves the interconnection of machines and systems, creating an intelligent network capable of autonomously monitoring the entire production process.

This interconnected system, driven by IoT (Internet of Things) and powered by AI (Artificial Intelligence), can make data-driven decisions to optimize and streamline operations, making the production process as efficient and profitable as possible.

Augmented Reality in Industrial Environments

There are several applications of AR to improve operational efficiency in Industry 4.0, but the following stand out.

SUPPORT & MAINTENANCE

t is common for engineers and operators in the factory to need support during production and maintenance. The sooner they receive this support, the less time and money the company will lose.

By equipping spaces and machinery with digital information thanks to augmented reality (Smart Spaces), operators instantly access key information, such as operating manuals, drawings, technical specifications and maintenance records, thus improving operational efficiency and reducing downtime.

The connection to IoT devices also allows access to real-time information (such as pressures or temperature), which is displayed overlaid on the environment.

Onirix’s Spatial AR technology allows Smart Spaces to be created simply, providing autonomy, scalability and low hardware investment. Both the scanning of the space and the subsequent visualization of the experience in augmented reality can be done through a smartphone or tablet.

INDOOR NAVIGATION & LOGISTICS

Augmented reality is helpful in providing clear, visual guidance inside buildings, such as warehouses or plants. Especially in large enterprises, AR can simplify navigation through complex facilities, enabling quick location of needed items.

In addition, by combining indoor guidance with augmented reality content, we can significantly improve worker efficiency as shown in the following video.

TRAINING

According to a report by Deloitte Insights, AR can improve information retention by up to 80% compared to traditional methods.

According to Harvard Business Review (HBR), the use of AR in employee training can reduce training time by 40%.

Tools such as Onirix allow you to simulate a 3D object or environment, creating an interactive replica that can be viewed in AR from multiple devices without the need to be in a specific room or in front of machinery.

This flexibility improves accessibility and immersion through the use of computers or touch screens (3D only – less immersion), smartphones and tablets (3D or AR – medium immersion) and virtual or mixed reality headsets (maximum immersion).

In this way, use cases are enabled for training in industrial environments with complex interactions, disassembly of objects, or even customized questionnaires for each worker.

In the following video you can see the success story of Edibon, a worldwide reference company in didactic equipment for engineering and technical education, which has used Onirix to improve its training experience.

MANUFACTURING

AR enables improved product design and development by superimposing, in real time, digital information on physical production environments. This allows engineers and designers to visualize and interact with 3D models directly within the actual production space.

This capability facilitates the early identification and correction of design errors, ensuring that potential problems are addressed before they affect the physical prototype stage. As a result, companies can significantly reduce the number of actual prototypes required, streamline the development process and accelerate production timelines.

In addition, augmented reality provides contextual guidance and feedback during assembly and quality control, further improving efficiency and reducing costs.

MARKETING & SALES

Finally, AR can have a significant business impact by allowing you to explain complex concepts visually, making them easier for your potential customers to understand.

It also allows you to showcase in a showroom models of machines that are too large or expensive to bring to a trade show or to customers’ offices. Customers can see and interact with the product in a whole new way.

That is the case of the following LG success story, which thanks to Onirix can demonstrate in a simple way how its aerothermal systems work.

In short, the incorporation of augmented reality into the realm of Industry 4.0 or even 5.0 represents a revolutionary breakthrough with the potential to radically transform the industrial sector. From improved product design and manufacturing process optimization to maintenance efficiency and innovation in training programs, AR offers significant benefits.

As this technology continues to develop, its impact on industry will only grow, driving innovation and efficiency to unprecedented levels.

The convergence of AR with Artificial Intelligence, what we at Onirix call “AIR” (Augmented Intelligent reality), opens up an even wider range of possibilities. Imagine personalized training programs or the ability to interact with physical spaces and receive immediate responses in augmented reality.

Undoubtedly, we are facing an exciting and promising future in which technology and industry are advancing hand in hand towards new frontiers. Visit our AR for Industry page if you are interested in this topic.